Hydraulic head test

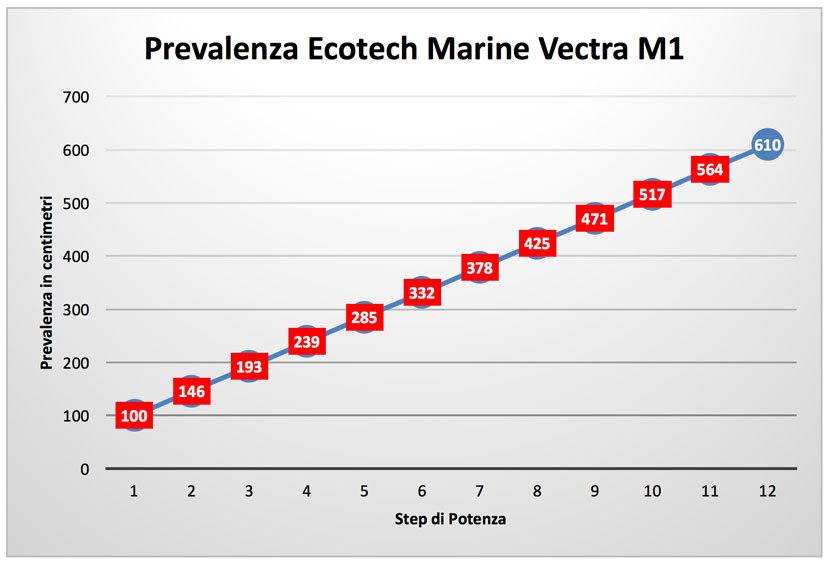

The hydraulic head has been the first thing we tested. As you know it’s the capacity of the pump to lift the water over a certain height. The test is very simple, but this time it was more difficult because of the declared value of 6,5 meters. That’s why we couldn’t measure it for each step, as usual.

As you can see in the picture we assured the tube the to the railing of the second floor and we turned on the pump at its maximum power, helped by my little daughter Arianna. We waited about 10 minuts for the pump to stabilize and then we done our measurement. We applied a plastic band from the balcony in the point where the water reached its highest. Then again we did the same to the bucket with the level of the water. Remember that the hydraulic head is the difference between the two quotes.

So we measured the distance between the two bands once removed the tube.

We registered a maximum level of 6,1 meters against the declared 6,5 meters. In the graphic here above the only measured data was the maximum level; the others have been esteemed (in red) just for having an approximate idea. We don’t have the minimum because when we figured out that it was missing we had already given it back.

The gap between the measured hydraulic head and the declared is of 6%. It’s a very remarkable result considering the sizes.

Flow rate tests

Measuring the flow rate was easy, thanks to the flow meter DigiSavant DIGIFLOW 6710M. At first we connected our tubes to the flow meter, as you can see in the picture below, where we received some help from Arianna.

Our results were very inferior to the declared ones. So we moved close the exit of the pump and the flow meter using less tubes as possible. Here below you can see the best we could do.

Our meter is 3/4 inches like the exit connection of the Vectra M1.

If you multiply the result by 60 you will obtain the liters per hour. This measurement is valid only with our conditions. The connection tube shouldn’t have losses.

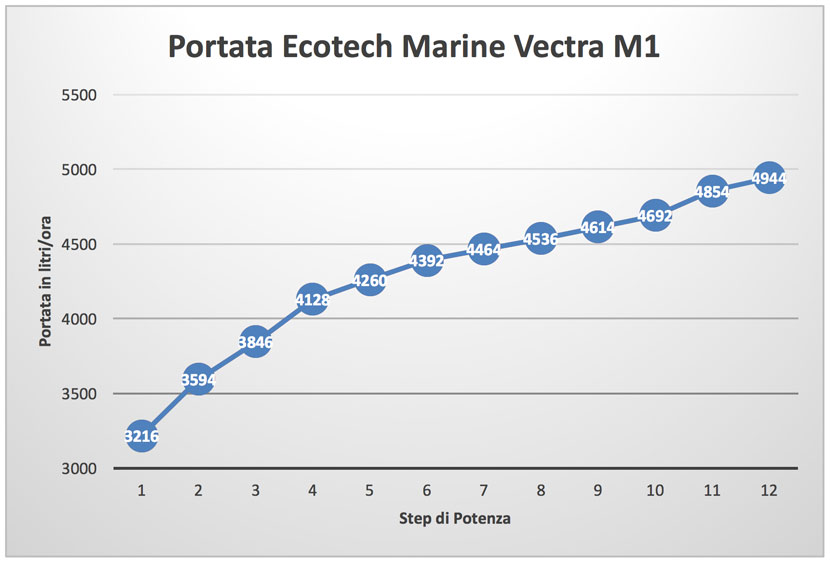

We measured the flow rate for each power step in order to have a better view of the distribution of the flow rate.

The maximum at the beginning was of 4.944 l/h (that is 82,4 l/m*60), very much inferior to the declared 7.500 l/h. So the pump reached the 66% of the declared value, in our test conditions. It’s a bit low, but if you have ever read our reviews, no other electronic pump has reached its maximum. So the 66% is a value just below the average.

Here our measurements:

When you use a return pump you have to be careful not to decrease the flow rate. Use the supplied hose clip and a tube large enough. It has to be the shorter than possible and make less 90 degrees curves as possible.

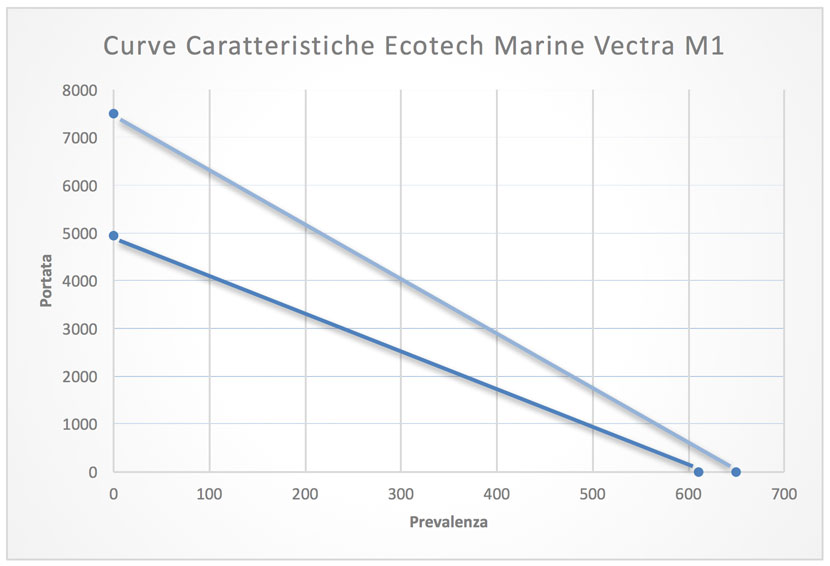

Characteristic curve

The characteristic curve is that specific curve which connects the various values of the flow rate to the hydraulic heads. It’s impossibile to recreated without a proper equipment. In this case it was even more difficult, so we just unite the two extreme points of flow rate and hydraulic head. The higher curve represents the project’s data.

So you can see on he left that the difference between our measured flow rate is wider than the hydraulic head. The area between the lines is what we expected to see, but it’s what we missed.

That is that if you take your flow rate, for example 300 cm, you have an ideal line to the value 300 of the hydraulic head. Where this line crosses the characteristic line you will obtain its specific flow rate. With the Ecotech Marine Vectra M1 you should have a flow rate of (more or less) 2.500 l/h against the declared 4.000. In the aquarium this will get worse because you will have to consider the tube’s friction and the eventual curves.

If you want to determine the flow rate of your aquairum here’s a useful article with acalculator: The automatic calculation of the flow rate.

Consumption test

To determine the consuption has been possible thanks to the useful RCE PM600 which is able to measure the Cos(fi) (or power factor) too. The result is already given in watt.

The consuption is very regular at the beginning. Then it changes in the upper-middle part and it presents a gap still remaining near to the last three measurements. The consuption goeas from a minimum of 25 watt to a maximum of 89,6 watt. The maximum declared consumption by Vectra M1 is about 80 watt. So according to our measurements we’re the 12% over the declared limit.

Here below the values for each power step.

Thanks to the RCE PM600 we also measured the cos(fi) at the maximum flow rate and hydraulic head, that is 0,93 with 89,59 watt of consumption. The magnet is made by ferrite, according to Ecotech Marine.

So at the maximum power the 93% of the electric current is active, that is 83,6 watt, what we pay in the bill. The part of the apparent current, 6 watt (89,6-83,6 watt), isn’t counted by the domestic counter so we aren’t going to pay more. This happen for any pump.

If we consider a consumption of 83,6 watt, and a price of 0,27 euro per kwh, we could use this pump continuously for an entire year at its maximum power, with a consumption of 732 kwh, with a price of 198 euro a year, or 16,5 a month.

We couldn’t do our usual noise test due to the dimensions of the pump and the lack of a proper space, but we can assure you that it seemed very quiet. Just an electric hiss at its maximum power.