Assembly

The assembly of the calcium reactor is extremely simple and it’s practically impossible to be mistaken thanks to the very easy functioning method and the very useful manual that explains (even with illustrations) how the connections have to be done.

The UltraReef UCS 140 reactor is obviously waterproof, so it can be used both internally and externally. In case you want to use it externally I suggest you not to put it on the floor but to place it inside a small plastic box in order to prevent an eventual micro water loss or a overflow from the various connections of the john guest type.

The characteristics of the pump are the following ones, and, in brackets, the measured values in our test:

| Sicce Syncra 2 | |

| Flow rate | 2.150 l/h (1.944) |

| Hydraulic head | 2 m (2) |

| Consumption | 32 w (31,1) |

| Length | 123 mm |

| Width | 85 mm |

| Height | 105 mm |

| Annual electric energy cost | 76 euro (energy cost 0,27 € a kwh) |

The favorite filling material for this type of reactor with diffusion from the bottom is, with no doubts, the medium-sized coralline reef and the jumbo coral, even the ARM, especially the coarse grain one, it shouldn’t be a big problem seen the diffusion system. For this test, considering that in the previous 120 I used the coralline, I wanted to try the ARM that’s a bit more problematic, to me.

Anyhow, I wouldn’t suggest the use of materials like the calcium carbonate. In fact in presence of compact materials the diffuser couldn’t guarantee the pH stability for all the column of the reactor. Moreover, and maybe this is the worst problem, a thin material could go inside the diffuser and worsen the outcome of the same reactor. But this problem doesn’t show otherwise.

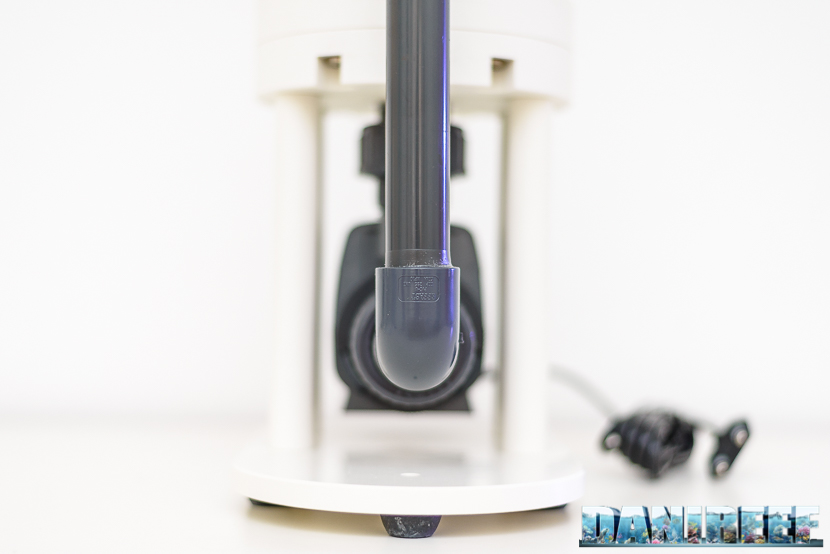

After connecting the pump under it and placing the reactor in sump it’s possible to connect the pipes, the bubble counter, the non-return pump and the CO2 tank.

Here below you can see the pipe with deviation supplied UltraReef, a choice I really appreciate.

Here below you can see the tap provided by UltraReef, the functioning has always been impeccable with the coralline, while with the ARM I’ve always found some problems.

During the use we didn’t have any problems to report, in over 6 months of intensive use it didn’t stopped, except when I ordered so, and it has always worked like a clock, even in presence of blackouts, true and faked, where it restarted its activity with no problems when the electric power turned back.

Filling system of the material

The loading of the material is from above, like in any other calcium reactor. In order to proceed you need to unscrew the 6 titanium screws (they were 8 in the previous reactor) and extract the superior cap, with all the connecting pipes. Before you have to arrest the alimentation to the CO2, to the recycling water and to the pump, so you can work directly in sump, without the need to extract anything.

I like the system through screws because it allows to work in sump without the need to extract the reactor.

If you want you can completely disassemble the reactor that becomes inspectable. In this way you it’s possible to be cleaned without any particular effort. I suggest you to do this operation at least once a year.

How to calibrate the calcium reactor UltraReef UCS 140 manually

This year I used the manual calibration for the calcium reactor. The operation is extremely simple. The regulation of the reactor is, anyhow, very simple and it has to be done adjusting manually the number of bubbles of CO2 in entrance through the the pressure reducer in the CO2 tank, balancing them with the drops exiting from the reactor, through the tap provided.

I suggest to begin, generally, with a CO2 bubble in entrance every 2 seconds and a water drop in the second exiting the reactor. The builder suggests to start with a bubble per second. Managing the CO2 will adjust the internal pH while the managing of the drops will adjust the total balancing. So, the CO2 in entrance, and the internal pH, indicate how much melted material I can put in the tank. At the end of a correct calibration of the reactor you can proceed with the control of the values of Ca, kH and Mg before the installation of the reactor itself. After that you can assemble and calibrate it, and after waiting for at least a day you can proceed with another turn of measurements, one in tank and another in exit from the reactor, to see if the contain of Ca and Kh is sufficient.

At this point you will compare the the values in exit from the reactor and the ones in tank. In order to have a great efficiency the reactor should have Kh higher than 30 in exit, so if at the second measurement the Kh is lower, you have to increase the CO2 bubbles in entrance, without changing the drops in exit. You have to wait another day and do again the measurements. Once the Kh will be higher than 30 (but 35 or 40 will be good), you will have to compare the value of Ca in the tank before and after the assembly of the reactor. If the value is decreased you have to increase the exit, if the value is unchanged it’s already ok, if the value is increased too much you can slightly lower the number of drops in exit. At this point you may have a small problem, because while you change the flow in exit the internal pH will also change: with the same quantity of CO2 you will have to treat more or less water. So you should slightly change the CO2 bubbles through the increase or decrease of the flow. You need to consider that with time your corals will grow and they are going to need even more calcium so occasionally you will have to recalibrate the reactor. Given that over the time the filling material will decrease inside the contact column, the efficiency will also decrease, I suggest you to have the reactor full for at least 3/4 and to often refill it.

The calibration with pH probe and solenoid valve

In order to make things easier for us and to have a “potentially” best outcome it’s possible to use a solenoid valve controlled through a pH probe, to be insert inside the contact column. In this way the probe will read the value inside the reactor and we will be able to adjust the solenoid valve so that it will allow the supply of CO2 if it’s too much. Normally you can begin the supply of CO2 over a pH value of 6.25. The bubbles in entrance of CO2 should have a frequency of more or less 2 bubbles per second, but not beyond.

The use of the solenoid valve is beneficial because of its supply continuity of the calcium reactor. It will have almost constant values even with the decreasing of the material, and in particular it will avoid an overdose of CO2 due to the decrease of the material or changings of flow rate by the supply pump. The only problem is doing the constant calibration of the pH probe that could “get tired” after a certain time, more or less 40/45 days, and you have to recalibrate it based on your own experience.

For the ones who want to obtain the maximum from a perfect regulation of the calcium reactor, you should do the following valuation, indicated especially for all those aquarists with problems of inferior algae in tank, that as we all know are stimulated by finding a low pH in aquarium. The lowering of the pH of the aquarium due to the exit of water with low pH becomes very critical at night, so thanks to the use of the solenoid valve and a timer, or a programmable computer, the calcium reactor could work just during the day, blocking the exit in the night hours by turning off the external supply pump, but leaving in function the recycling pump and the command of the CO2 by the solenoid valve. In this way you can avoid to contribute to the decrease of night pH. The water in the reactor would continue to be in recycling and the CO2 wouldn’t be dosed because it’d be controlled by the solenoid valve, so without problems of stagnation of the water neither an excessive amount of CO2 in the reactor.

The article continues and ends on page three with our conclusions.