The Teco booth awaited us with a surprise. Three chillers in comparison in order to see the differences between their costs.

The Teco booth awaited us with a surprise. Three chillers in comparison in order to see the differences between their costs.

This article is also available in: ![]() italiano

italiano

This was the first thing we noticed at the booth of the company from Ravenna: three chillers, one of which I knew very well because I kept it at home and reviewed. Back to 2010. If you are curious, you can read again the review of the TR15 at this page, brother of the TR20 on show.

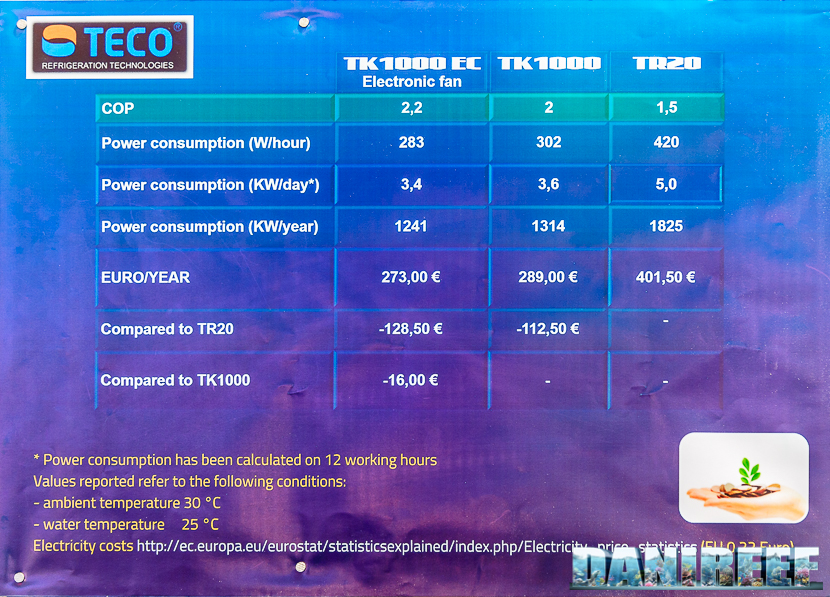

The three chillers, TK 1000 with electronic vent, Tk 1000 and TR20 were connected to the same aquarium, so with the same temperature. After the warm-up, when the chillers were working, you could appreciate the difference of efficiency between them, even if they had (more or less) the same refrigerating capacity.

The bigger difference, as expected, was between the TK brothers and the older series. The COP, in fact, was deeply different. It switched from a 1,5 to a 2 and 2,2. The COP, Coefficient of Performance, indicates the level of removed heat in a system compared to the work done.

So: from the 420 watt of the TR20 it goes to the 302 of the TK 1000 and to the 283 of the TK 1000 with electronic vent. The return in the cooling is about 630 watt for the TR20, 604 and 622 respectively for the two TK. The difference is incredible and here below there’re the pictures of the two displays of the current indicators.

So: from the 420 watt of the TR20 it goes to the 302 of the TK 1000 and to the 283 of the TK 1000 with electronic vent. The return in the cooling is about 630 watt for the TR20, 604 and 622 respectively for the two TK. The difference is incredible and here below there’re the pictures of the two displays of the current indicators.

The chart given by Teco was there to remember what this means. If you count 12 hours of work at day there’s a saving of 48 kWh a month. And I have to say that the valuations with the energy costs of 0,22 used by Teco are too conservative for Italy. I have personally seen contracts of 0,27/0,28 euro per kwh.

The news of the 2018 is Teconnect to connect the chillers on internet

But the true news of the 2018 is Teconnect. A device to be connected to compatible Teco chillers (not the old ones) that through an app allows to control your own chiller, visualize the temperature and see the different charts of the evolution of the temperature of the aquarium.

Here above there’s the device to be connected to the chiller. It’s magnetic so it can be attached everywhere on the chassis.

Here you can see how it hooks through a cable to the chiller, and that the lack of this, obviously, can’t allow the connection with older chillers.

Here you can see how it hooks through a cable to the chiller, and that the lack of this, obviously, can’t allow the connection with older chillers.

On our device it’s possible to see directly the display of the chiller, which works with the same logic of the chiller itself. In this way the user isn’t confused and can work with it as he were physically in front of the chiller.

It’s not truly indispensable but it expands the versatility of the chiller. And I’m sorry I can’t implement it without changing mine… It’s a feature I really like to have.

Well, I have the small TK 150 (review) that you can see here below, but for the future I can’t tell…

Teco booth and the new factory location

The booth was particularly wide, as it made us used to, and this time it shown us another one of the important news of this year by Teco.

On the background, in fact, it’s possible to see the new factory location where Teco has just moved. It’s at Ravenna, not so far from the old location, but completely new and avant-garde. And it was put in evidence in the big booth of Teco.

On the background, in fact, it’s possible to see the new factory location where Teco has just moved. It’s at Ravenna, not so far from the old location, but completely new and avant-garde. And it was put in evidence in the big booth of Teco.

ATM – Acrylic Tank Manufacturing

Part of the booth was occupied by ATM, the american producer of which Teco has become the distributor in Europe, except for Great Britain, two years ago.

In the last few months we tested very different products and the little we can say it’s that we like them.

In the last few months we tested very different products and the little we can say it’s that we like them.

References

For other informations about Teco products we sent you to the official site. The same for ATM. We invite you to read our Editorial about the exhibition to know our point of view about this Edition of the Interzoo 2018 and to consult the links of the articles dedicated to the booths we’ve seen until today: