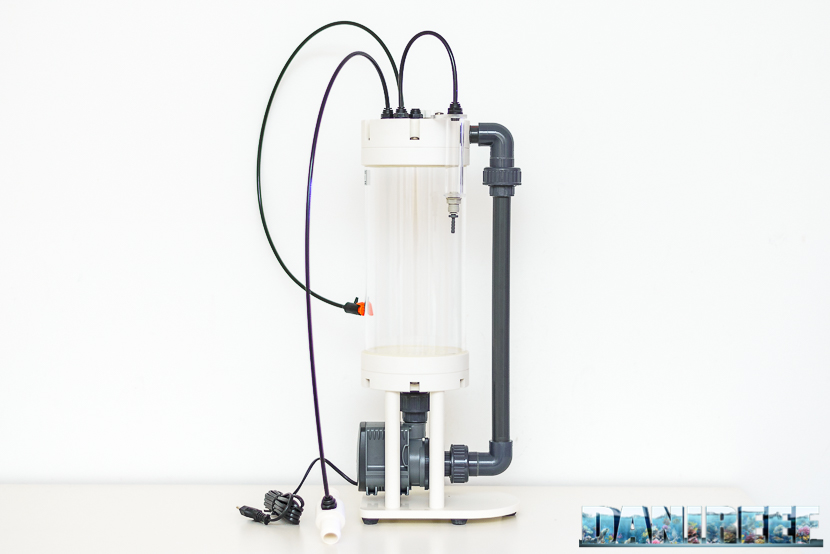

Finally we can talk about the calcium reactor UltraReef UCS 140, suggested by the builder for aquariums until 500 liters, and tested in my reef aquarium of more or less 400 liters.

This article is also available in: ![]() italiano

italiano

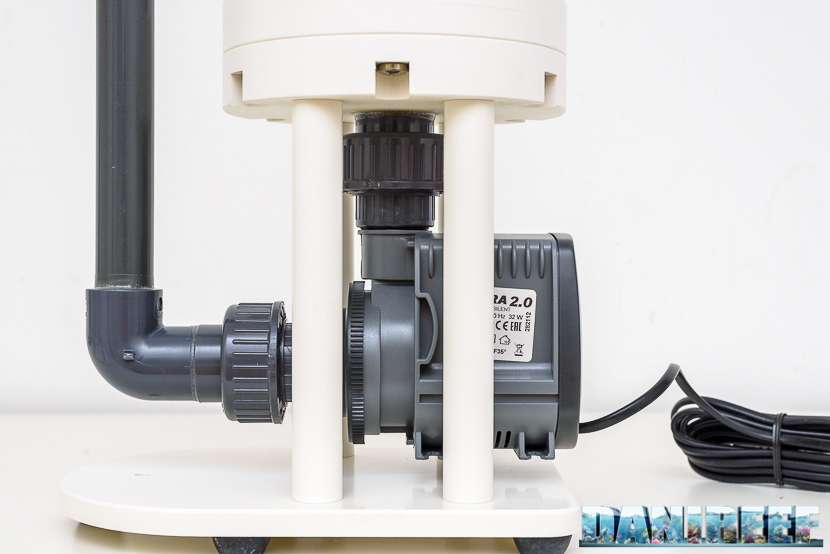

The reactor is equipped with just one pump, the Sicce Syncra 2.0 that we have tested in the past with a great outcome.

The UCS140 has a complete set of accessories for an easy use like the bubble counter and the probe holder. It’s only missing the feed pump – but the problem can be overcome by diverting the return pump, a method that I use for several years. But the same reactor has also a pipe with double probe holder and deviation to be installed on your own return pump. It’s a very useful device that allows us to have the calcium reactor ready to use, at least for what regards the “hydraulic” part.

For it to work it needs also the CO2 tank, the pressure reducer and the eventual connecting pipes.

Technical characteristics:

| UltraReef UCS-140 |

|

| Height of the reactor | 660 mm |

| Diameter reactor’s external pipe | 140 mm |

| Acrylic thickness | 3 mm |

| Overall dimensions | 150×220 mm |

| Pump | Sicce Syncra 2 (review) |

| Useful filling height | ~ 25 cm |

| Hydraulic head | 3,5 liters |

| Price | 459 euro |

| Annual cost of electricity | 43-54 euro |

The reactor is very beautiful to be seen, and impeccably built with acrylic in the central column and full turned for the base and the cap. The connecting pipes are in grey stoke PVC. We always hope that UltraReef begins to use the white PVC instead. We don’t know how much more it will cost, but it would be incredibly nicer… don’t you think?

One of the distinctive traits of the reactor is that it’s completely built in Italy, and it uses also an italian pump (Sicce).

The screws used are in titanium in order to resist corrosion.

The functioning principle

From the point of view of the construction the reactor is a standard cylinder classic arrangement, with an external water recycle, leaving the inner cylinder completely available to the material. The water is moved by an external pump (not provided) or the deviation on the return pump directly under the cap of the reactor. From here it is aspirated by the pump that mixes it with the CO2 and pulls it to the base of the reactor where it will be spread through a circular pierced plate of 14 cm of diameter.

The Sicce pump is capable of a flow rate of 1.944 l/h and 200 cm of hydraulic head.

The pump under the contact chamber, and it’s predominantly so wide because usually the reactor are placed in sump, it allows an adequate cooling of it, extending its duration.

Over the cap, as we see in the following picture, we have the probe holder, the entrance of the CO2 coming from the bubble counter, and the central air vent. Extremely useful.

Having the type of construction, the recycling of the CO2 is always guaranteed thanks to concave construction of the covering cap. It completes the reactor dotation the valve for the partialisation of the outgoing water that should be a great Kleber.

The article continues on page two with the assembly, topping up system and the calibration.